Team 3: Materials Modeling: Shear Band Formation in Bulk Metallic Glasses

Presenter

August 7, 2013

Abstract

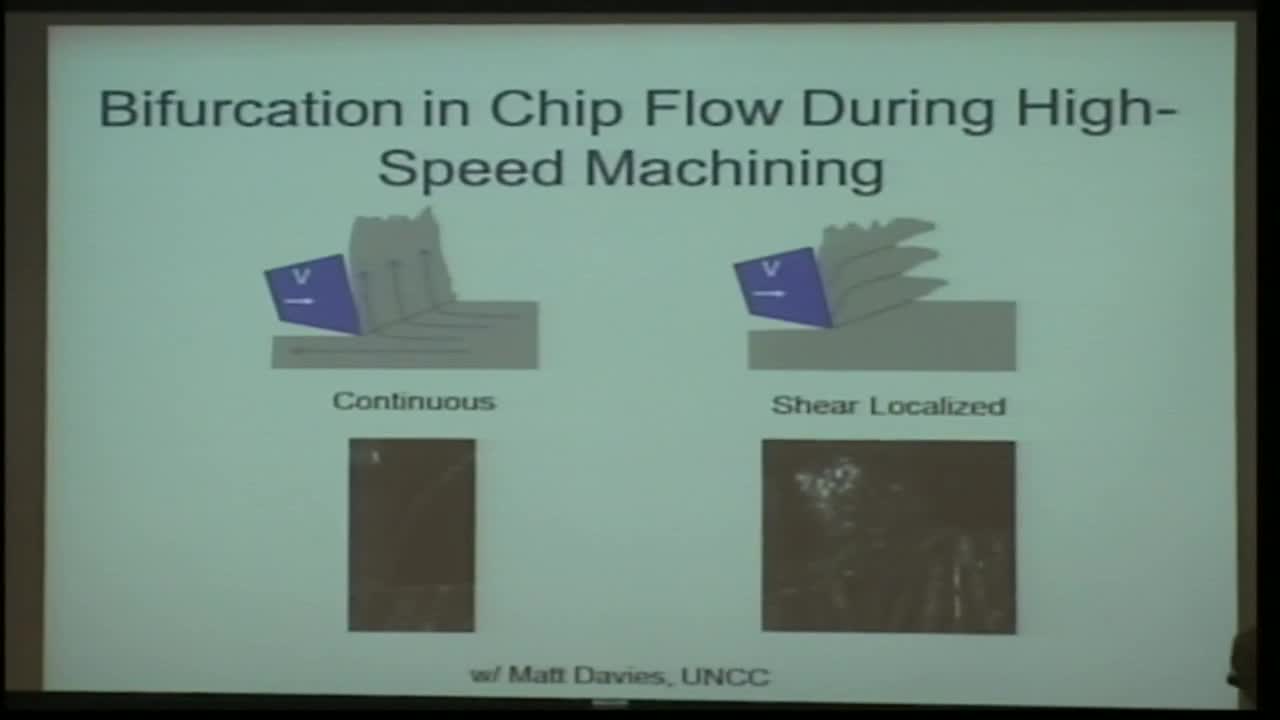

About thirty years ago, the problem of the localization of rapid plastic deformation of a number of polycrystalline metals into adiabatic shear bands began to receive considerable attention, mainly due to its connection with military applications, such as armor penetration. However, the phenomenon had been observed much earlier in metal machining operations (see Figure 1). At faster cutting speeds and larger depths of cut, the strips of work material, removed by machining, called chips, were often observed to exhibit considerable structure, as a bifurcation took place in the material flow, from continuous, or fairly smooth chips, to serrated, or shear localized chips; see Figure 2(a).

The generally accepted explanation for the onset of this shear localization is that the tendency of a metal to work-harden with increasing deformation is overcome by a competing tendency for the material to soften, due to heat production caused by the rapid shearing. The term adiabatic refers to the fact that the time scale for heat conduction is much larger than the time scale for heat generation by plastic working. Recently, there has been a growing interest in the machining of amorphous metallic alloys, which are also called bulk metallic glasses (BMG). These materials differ from common polycrystalline metallic alloys, because their atoms do not assemble on a crystalline lattice, and as a result, they have unique physical, mechanical, and chemical properties. What is interesting is that a number of BMG’s have been found to produce shear-localized chips during machining operations; see Figure 2(b). Furthermore, a number of theoretical studies have argued that this strain localization is controlled not by rapid heating, but rather by a change in the concentration of free volume in the material.

In this project, we will investigate shear band formation in a BMG by studying a geometrically simple deformation of the material, a homogeneous shear flow. Our analysis will mimic some of the analysis that has been done to study adiabatic shear band formation in more common metallic alloys. We will perform a linear stability analysis of the homogeneous shear flow. The difficulty here is that, because the reference shear flow solution is time-dependent, so is the matrix of the linearization of the model equations about the reference solution. An approach that has been frequently used in this field is to apply the method of “frozen” coefficients, and this is where we will begin.

Figure 1. Schematic of a cutting process. The cutting tool moves across the workpart and a chip is formed in front of the tool.

Figure 2. Chips from two materials being machined.

(a) 52100 Bearing Steel (Grain Size:10’s of μm) (b) Nickel=Phosphorus (Amorphous)

References:

R.J. Clifton, J. Duffy, K.A. Hartley, and T.G. Shawki, On critical conditions for shear band formation at high strain rates, Scripta Metallurgica 18 (1984) 443-448.

L.H. Dai, M. Yan, L.F. Liu, and Y.L. Bai, Adiabatic shear banding instability in bulk metallic glasses, Applied Physics Letters 87 14196 (2005).

R. Huang, Z. Suo, J.H. Prevost, and W.D. Nix, Inhomogeneous deformation in metallic glasses, Journal of the Mechanics and Physics of Solids 50 (2002) 1011-1027.

M.Q. Jiang, L.H. Dai, Formation mechanism of lamellar chips during machining of bulk metallic glass, Acta Materialia 57 (2009) 2730-2738.

T.W. Wright, The Physics and Mathematics of Adiabatic Shear Bands, Cambridge University Press, 2002.

Prerequisites:

Interest in computing (Matlab or C/C++). Background in ordinary differential equations; some linear algebra.

Keywords:

Materials modeling, shear band formation, machining.