Asymptotically Optimal Inventory Control for Assemble-to-Order Systems

Presenter

May 16, 2018

Keywords:

- inventory management, stochastic control, stochastic program, asymptotic optimality

Abstract

The assemble-to-order (ATO) system is a classical model in inventory theory, where multiple components are used to produce multiple products. All components are obtained from an uncapacitated supplier after a (component dependent) deterministic lead time, while demand for the products forms a compound Poisson process. Assembly is assumed to be performed instantaneously, so all inventory is held as components rather than finished products. Demand that is not met immediately is backlogged. The optimal control for this system (where the goal is to minimize the long run average inventory + backlog cost) is not known except for some very special cases.

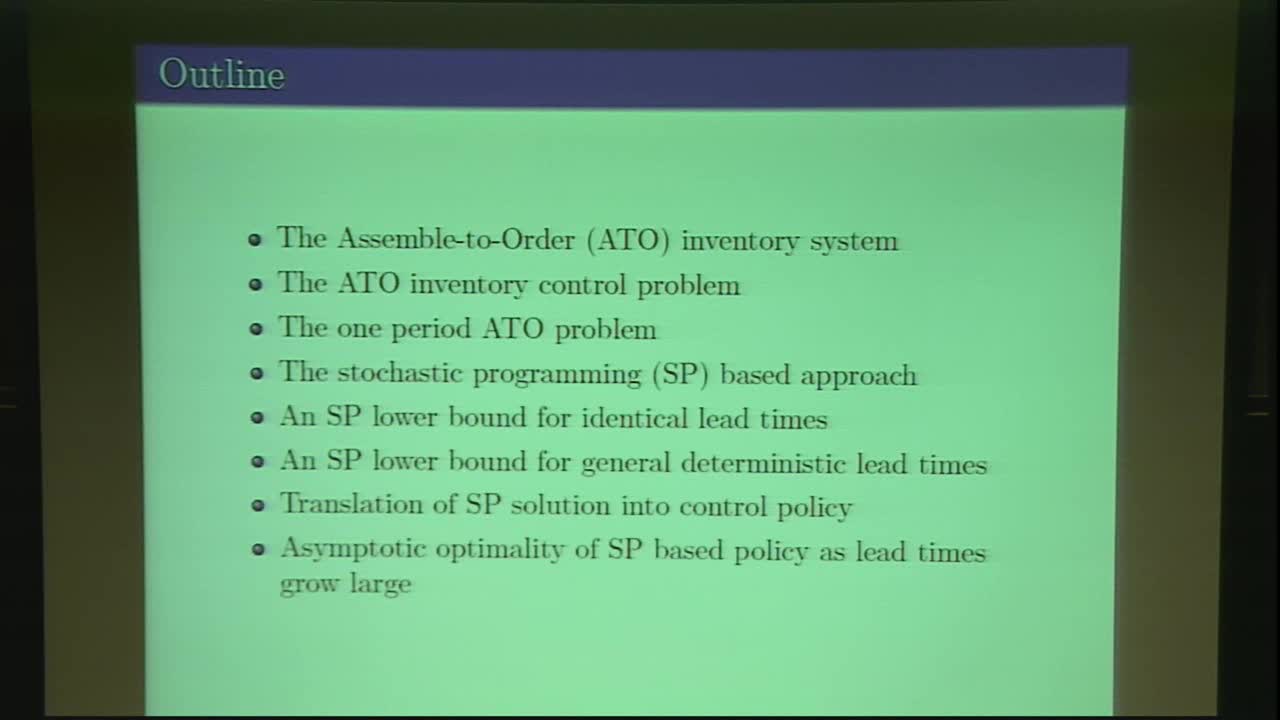

In this talk we present an approach to this problem based on the solution of a related stochastic program (SP). The SP has K+1 stages, where K is the number of distinct lead times. We show that the SP provides a lower bound on the achievable cost under any feasible policy, and provide a ‘translation’ of the solution of the SP into a policy for the inventory system. Finally, we show that this policy is asymptotically optimal as the lead times grow large.

(This talk is based on joint work with Mustafa Dogru, Qiong Wang and Haohua Wan.)